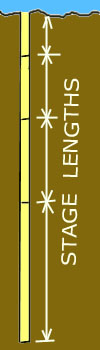

When grout holes are longer than about 30 ft [10 m], it is usually best to divide them into shorter lengths, called stages, and grout each of these stages separately. This can produce better grouting because:

- Settlement of cement and rise of bleedwater is less. These affect the quality of the grouting.

- Pressures can be controlled to a greater degree, and upper stages are exposed to less pressure than if stages are not used.

- Leaks and connections can be handled with less trouble

- If drilling water is lost because the bit has broken into a wide crack or void, drilling can be stopped and a special stage made. This provides individual grouting of the feature. Then regular drilling and grouting can proceed with far less trouble.

- Similarly, if a zone is reached where soft or broken rock collapses into the hole appreciably, treatment can be provided by stopping drilling, making a special stage, and consolidating the bad area by grouting. However, if long lengths of hole collapse, special drilling and grouting methods may be needed.

Common practice is to have relatively short stage lengths near the surface and to increase the length as holes get deeper. This practice largely reflects considerations about the effects of pressure. Long stages have greater pressures at their top than shorter ones do, and the surface regions are less able to stand substantial pressures than the deeper ones.

Lengths of planned stages should be multiples of drill rod lengths to make each rod change worthwhile. Rods usually come in 10-ft [3 m] lengths. In weak rock though, deep stages should not be much longer than surface ones.

Stage Grouting Methods

Methods for grouting a stage include:

- DOWNSTAGE WITHOUT PACKER

- DOWNSTAGE WITH PACKER

- UPSTAGE

Details of these methods follow here:-

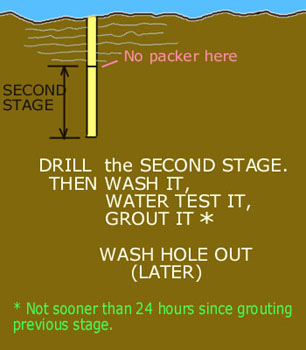

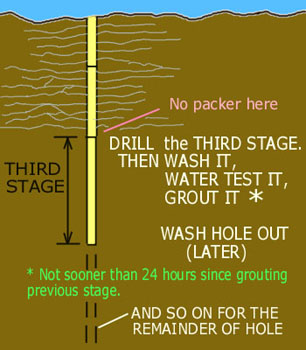

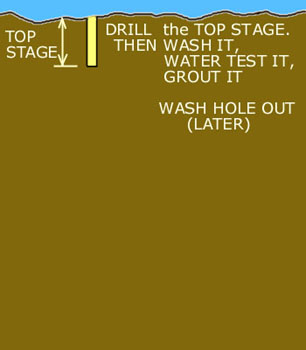

DOWNSTAGE WITHOUT PACKER

The steps are:-

The method is also called "Stage Down" and "Descending Stages."

As the name indicates, this is a method where the top stage is grouted, followed by the second, and so on down the hole, and a packer is not used to separate the stages.

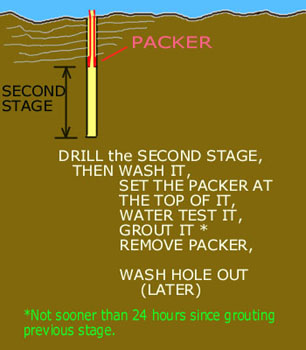

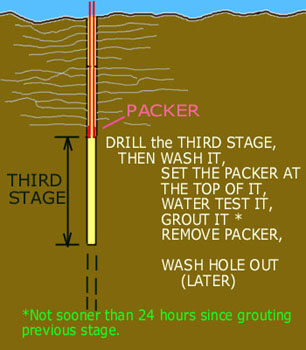

DOWNSTAGE WITH PACKER

Also called "Stage Down", "Stage Grouting with Packer", and "Stage Grouting." This is the same as the previous method except that a packer is used to prevent grout entering stages above the one being grouted.

UPSTAGE

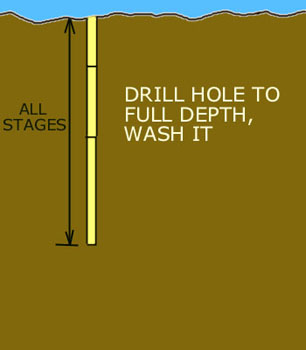

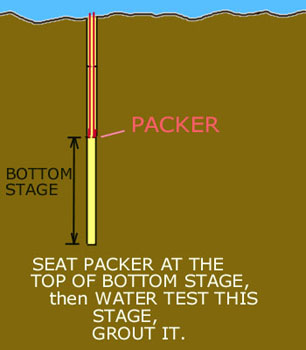

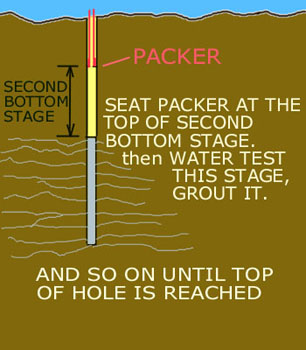

Also called "Packer Grouting", "Stage Up", "Stop Grouting", "Stage Grouting", and "Ascending Stages." This grouts the hole from the bottom up. The hole is drilled full depth before starting grouting.

Practices vary about the time interval between grouting of stages. Some lift the packer as soon as pressure dissipates in the stage just finished and then immediately start the next stage, whereas others wait at least 6 hours between stages.

THAT COMPLETES THIS PROGRAMME

SOME INFO....

This is an abbreviated extract from Version 8.0 of the series of ROCKGROUT grouting programmes. The version is on DVD but is not yet publicly available

The DVD contains the book Construction and Design of Cement Grouting together with the contents of this Web site and some additional matter.

....and here is a suggestion: If you have reached this page without going to "HOME", then go there now to get access to the many pages listed there.